viliina ma fa'apipi'i masini fa'afefiloi

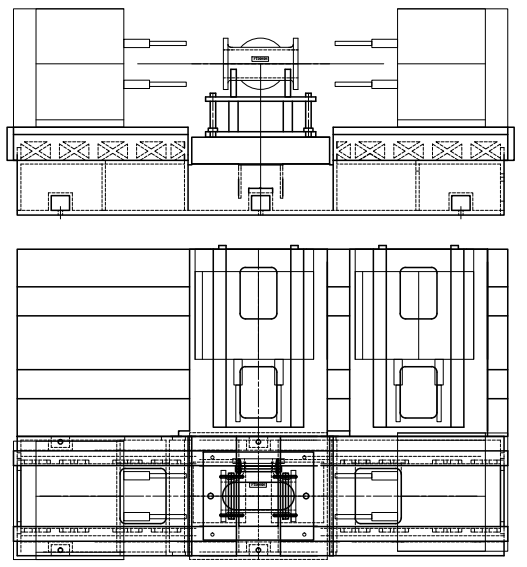

O lenei masini masini o se fa'alava CNC tolu-itu vili ma tapping meafaigaluega masini tuufaatasia.O ulu agavale ma taumatau o lo'o aofia ai le laulau fa'ase'e fe'avea'i hydraulic ma le atigipusa;o le vaega lona tolu e aofia ai le CNC feaveai sliding laulau ma le atigipusa pusa (vaevae i ni vaega se lua: vili ma tapping).O le ogatotonu e aofia ai le fale faigaluega, mea faʻapipiʻi eletise ma isi vaega, ma faʻapipiʻiina i le kapeneta eletise tutoʻatasi, nofoaga eletise ma masini faʻapipiʻi.O le mea faigaluega o lo'o si'i ma le lima ma fa'apipi'i fa'alelei.Va'ai le fa'asologa o masini mo fa'amatalaga.

Fa'asologa masani o meafaigaluega:

①O le masini masini o se faʻatulagaga faʻatulagaina, tasi le vaega i le taimi, lea e manaʻomia ai se faʻamaufaʻailoga e faʻaaogaina e fai ma faʻamaufaʻailoga tulaga faʻapipiʻi i le faagasologa muamua.

②O le faiga masani o le: faʻamama le mea faigaluega-tuʻu le mea faigaluega e faʻagaioia i totonu o meafaigaluega-faʻapipiʻi faʻamalosi le mea faigaluega, o seti e tolu o faʻataʻitaʻiga galuega e mafai ona vave faʻafeiloaʻi ma osofaʻia, ma seti e tolu e mafai ona faʻamaopoopo pe faʻagasolo i laasaga, ma o seti e tolu o fa'ase'e e saosaoa Toe fo'i i le tulaga muamua-o le gutu ogatotonu e fa'asolo le fa'ase'e i le tulaga, ma fa'agasolo le ta'i.A maeʻa le gaioiga, o le tapping slide e toe foʻi i le tulaga muamua - faʻamalolo faʻasao - faʻapipiʻiina ma le laʻuina - ulufale i le isi taamilosaga.

O le meafaigaluega e faʻaaogaina le faʻaogaina o le liʻo pito i fafo o le tino o le valve avanoa, ma o le paʻu eletise i le pito i luga o le mea faigaluega e faʻapipiʻi ai le mea faigaluega.

Fa'aaogāga

O lenei masini e masani ona faʻaaogaina i le faʻaogaina o Valve, Pump body, Auto parts, Construction machine parts etc.E mafai ona galue mo le tele o faʻataʻitaʻiga, mo se faʻataʻitaʻiga, End face pu, Median orifice, Bore-hole and Sphere.It worked with Huadian PLC Controller, E mafai ona iloa otometi, maualuga saʻo, tele ituaiga ma tele gaosiga.

Vaega autu

(1) O lenei masini na galue ma Huadian PLC Pule, e mafai ona galue mo le tele o taualumaga, mo se faʻataʻitaʻiga, Faʻaiʻu foliga pu, Median orifice, Bore-pu ma Sphere.O le CNC Pule e lelei le fetaui lelei, mamana galuega ma faigofie faʻagaioiga.

(2) O le alalaupapa laulau fafaga Fafaga fa'aoga le u'amea lanu efuefu maualuga, fa'afefete fa'afefeteina, fa'afefe ma le matua togafitiga fa'atolu.Fa'ato'a fa'ate'aina le fa'alavelave fa'alotoifale, O le pito i luga o le ala ta'iala e fa'aaogaina ai le tineia o leo tele ma le maaa e o'o atu i le HRC55.E ala i le maualuga o le taʻiala faʻataʻitaʻiga auala faʻafefeteina, ia mautinoa le saʻo, faʻamalosi, mautu.

(3) O le vaega faʻasalalau e faʻaaogaina le faʻamalo saʻo polo ma le faʻaogaina e faʻaumatia ai le va, ina ia mautinoa le faʻaogaina o le masini.

(4) O le ulu malosi ua faʻapipiʻiina i le tolu - laasaga o le suiga o le saoasaoa o le tusi ma le afi malosi, ausia le saoasaoa maualalo ae maualuga le malosi, e mafai ona tatalia le mamafa o le tipiina, faʻaleleia le lelei o le gaosiga.

(5) O meafaigaluega faigaluega e faʻaaogaina ai le faʻapipiʻiina o le eletise-otometi, e faʻaleleia ai le lelei ma faʻaitiitia le malosi o tagata faigaluega.

(6) E faʻaaogaina e le masini le faʻaogaina o le uʻamea tutotonu, ina ia mautinoa o le faʻaogaina atoa o vaega feʻaveaʻi taʻitasi ona faʻaleleia ai lea o le ola tautua o meafaigaluega masini.

Fa'atonuga muamua

O la matou masini e masani lava ona aofia ai le tino, ulu malosi, CNC fafaga fa'ase'e laulau, mea faigaluega, ma fa'aauupegaina i se kapeneta eletise tuto'atasi, se nofoaga fa'atosina, se masini lubricating fa'atotonugalemu, se masini fa'amalo otometi e aveese ai masini, ma se masini puipuia maualuga.

(1) Tino

O le Tino e faʻaaogaina le tino tuʻufaʻatasia faʻatasi ma le tulaga maualuga, e ala i le faʻaogaina o le tusi lesona ma le matua togafitiga e faatolu.O le pito i luga o le auala taʻiala e togafitia e le super leo tineia, o le fausaga e talafeagai, e faʻamautinoa ai le faʻamalosi, saʻo ma le mautu o le masini.

(2) Le ulu malosi

O le tino o le ulu malosi o loʻo faʻaaogaina le sili ona lelei, faʻaoga mea faʻaoga 20GrMnTAi, faʻatasi ai ma le faʻamalosi, faʻafefeteina, carburizing ma tineia, maualuga saʻo le olo i fafo ma totonu. le milo.

(3) Le Fa'atonu

O le Fixture e faʻapitoa faʻapitoa mo mea faigaluega.O le poloka faʻatulagaina ma le pine faʻatulagaina o loʻo tineia, ina ia mautinoa le faʻalagolagoina o le tulaga o mea faigaluega.O lo'o fa'amauina e le eletise le mea faigaluega, e fa'aleleia atili ai le lelei o le gaosiga, fa'aitiitia le malosi o tagata faigaluega.

Mea faigaluega faʻamalosi eletise

O le fale eletise e faʻaaogaina le valve Superposition tutoʻatasi, lea e aofia ai se valve electromagnetic maualuga, o le faʻatonuina o le valve, o le valve throttle ma le pamu vane lua.Ma faʻapipiʻiina i le ea malulu masini e faʻamautinoa ai o loʻo i ai i le nofoaga faʻapitoa le suauʻu masani vevela pe a galue.

Kapoti eletise

O le kapeneta eletise e tutoʻatasi ma tapuni. Faʻapipiʻiina ma le CNC controller, Inverter ma eletise eletise. Faʻapipiʻi foʻi le mea e faʻafefe ai le ea e faʻamautinoa ai o loʻo galue lelei vaega eletise o le masini, leai se pefu.

- Fa'ailoga autu:

Max.vili le lautele(mm)

6-12

laulau galue(mm)

360×400

Tauagavale/Taumatau malaga(mm)

480

Malaga tu'usa'o(mm)

220

Saosaoa spindle vili

580

Malaga(mm)

230

Pu taper o Spindle(NA)

7:24

Malosiaga afi (KW)

2.2

Saosaoa o le ta'i (mm/min)

256

Malaga Fa'asaga'i(mm)

300

Pu fa'aipouli (NA)

7:24

Max.tapping(mm)

8-M14

afi eletise eletise(KW)

1.5