5-Axis Vertical Machining Center V5-700B

Vaaiga lautele

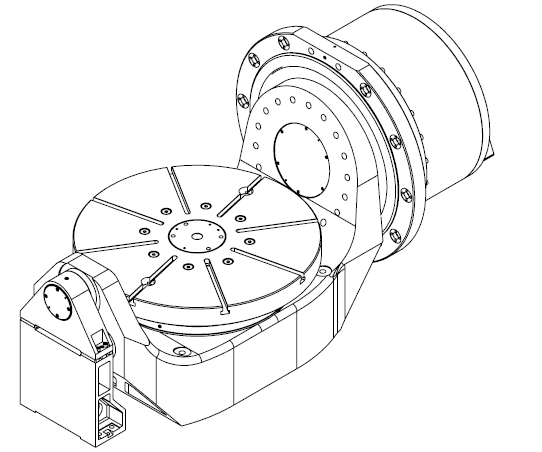

V5-700 B lima-axis machining nofoaga faʻaaogaina se faʻamautu C-foliga fausaga, ma ua faʻapipiʻiina i le eletise eletise, tuusaʻo-drive CNC turntable ma meafaigaluega mekasini e pei o tulaga masani, lea e mafai ona iloa le maualuga-saosaoa ma le maualuga-saosa machining o vaega faigata . E faʻaaogaina lautele i le fetuutuunai ma le faʻaogaina lelei o afi fou o taavale afi, gearboxes, afi, masini, masini faʻafomaʻi robotic ma isi oloa.

Fa'amatalaga o galuega ma foliga

1. Fa'asologa atoa o le meafaigaluega masini

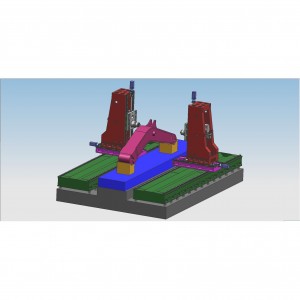

O le V5-700B lima-axis machining centre e faʻaaogaina se faʻamautu C-foliga fausaga, o le koluma o loʻo faʻamau i luga o le moega, o le ipu faʻasolo e alu faʻalava i luga o le koluma (X direction), o le nofoa faʻasolo e alu umi i luga o le ipu faʻasolo (Y itu). ), ma fa'agasolo sa'o le fa'aulu i luga o le nofoa fa'ase'e ( itu Z). O le laulau galue e faʻaaogaina le faʻavae tuusaʻo tuusaʻo e tasi-lima, ma ona faʻailoga eseese o faʻatinoga ua oʻo i le tulaga maualuga faavaomalo.

2. Faiga fafaga

X, Y, Z-axis laina taʻiala laina ma sikuli polo e maualalo static ma malosi feteʻenaʻiga, maualuga lagona, maualalo vibration i saoasaoa maualuga, leai se tolotolo i maualalo saoasaoa, maualuga tulaga saʻo, ma lelei le faatinoga o le taavale servo.

X, Y, Z-axis servo motors e fesoʻotaʻi saʻo ma faʻailoga polo maualuga e ala i soʻotaga, faʻaitiitia fesoʻotaʻiga vavalalata, iloa le leai o se vaʻaia, faʻafefeteina le fafagaina, faʻatulagaina saʻo, ma le maualuga o le faʻasalalauga.

O le Z-axis servo motor e iai se galuega taofi. I le tulaga o le faaletonu o le eletise, o le taofi e mafai ona otometi ona taofi mau le afi afi ina ia le mafai ona feliuliuaʻi, lea e faia se matafaioi o le puipuiga o le saogalemu.

3. Milo eletise

O le eletise eletise e faʻaaogaina le faʻaogaina o le eletise eletise maualuga (meafaitino pateni: 202010130049.4), ma o le pito e faʻapipiʻiina i nozzles malulu e faʻamafanafana ai le meafaigaluega. O loʻo i ai le lelei o le saoasaoa maualuga, maualuga maualuga, ma le maualuga o le tali malosi, ma e mafai ona iloa tulafono faatonutonu saoasaoa. Fausia-i le encoder maualuga-saʻo e mafai ona iloa le itu tonu taofi ma malo tapping.

4. Mekasini meafaigaluega

O le mekasini meafaigaluega tisiketi faʻaaogaina le BT40 manipulator tool magazine, lea e mafai ona faʻaogaina 24 meafaigaluega.

5. Lisi Lisi

O le tagata lava ia atiina ae tuusao cradle turntable (mea fou pateni 202010409192.7, 202010408203.X, 2022109170252) ua faaauupegaina i se encoder atoatoa maualuga-saʻo ma cooled e se vai cooler i se vevela faifai pea. E i ai le lelei o le maualuga maualuga, maualuga le saʻo, ma le maualuga o le tali malosi. O le laulau faigaluega e faʻaaogaina 8 14mm radial T-slots, faʻatasi ai ma le maualuga o le mamafa o le 500kg (faʻasagaga) ma le 300kg (tusaʻo)

| Malosi fa'atatau (kW) | Saisai fuatia (Nm) | Saosaoa fa'atatau (rpm) | Tulaga maualuga (Nm) | Fa'atatau i le taimi nei (A) | |

| B axis | 13.3 | 2540 | 50 | 4000 | 46.9 |

| C axis | 3.7 | 700 | 50 | 1400 | 14 |

6. Tapuni atoa faiga tali fa'aoga

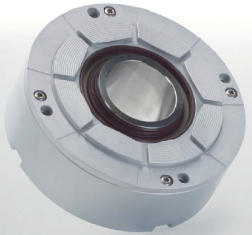

X, Y, ma Z laina laina ua faʻapipiʻiina i HEIDENHAIN LC4 faʻasologa o fua faʻatauga faʻatau; B ma C rotary laulau o loʻo faʻapipiʻiina i HEIDENHAIN RCN2000 faʻasologa encoders maualuga taua e iloa ai faʻamatalaga tapuni atoa o 5 feed axes, faʻamautinoa o le masini masini e maualuga le saʻo ma le maualuga. taofi sa'o.

Fa'aauupegaina i se vai malulu mo le malulu faifaipea e fa'amautinoa ai o lo'o lelei le galuega ma mafai ona ta'avale lelei mo se taimi umi.

O le pneumatic system e fa'amama e vaega pneumatic e iloa ai galuega o le fa'amamāina ma le feulaina o le pu taper o le 'au autu, puipuiga o le fa'amauina o le ea o le fa'amau autu, ma le liliuina o le mekasini meafaigaluega ma mea faigaluega.

8. faiga lubrication tutotonu

O le poloka fa'ase'e o le ta'iala ta'iala ma le nati o le sikulula polo e fa'aaogaina se masini lubricating fa'atotonugalemu ma ga'o manifinifi, lea e maua ai le lubrication masani ma le tele e fa'amautinoa ai le sa'o ma le mautu o le sikuli polo ma le ta'iala ta'iala.

9. faiga lubrication suauu-ea

O lo'o fa'apipi'iina le fa'avili eletise ma se masini fa'aulufale mai le suau'u-ea e fa'aulu atoa ai ma fa'alili le fa'amalo. Ua fa'aauupegaina le masini e tu'uina atu ai se fa'ailo mo le lubrication fa'aletonu, fa'amautinoa lelei e mafai ona galue lelei le spindle i le saoasaoa maualuga mo se taimi umi.

10. Mea faigaluega fua faiga

O le masini meafaigaluega ua faʻapipiʻiina i le HEIDENHAIN TS460 paʻi suʻesuʻe ma le faʻailoga uaealesi, lea e mafai ona faʻapipiʻiina i luga o le manoa e ala i le tusi lesona poʻo le faʻaogaina o mea faigaluega faʻapitoa e iloa ai galuega o le faʻaogaina o mea faigaluega, fuaina o mea faigaluega ma le seti faʻatulagaina, ma o le toe faʻaleleia o le ≤ 1um (saosaoa suʻesuʻe 1 m / min), o le vevela galue o le 10 ° C i le 40 ° C. O le HEIDENHAIN pa'i su'esu'e e fa'aosoina e se ki opitika. O le stylus e faʻaaogaina se faʻamaufaʻailoga e tolu e faʻamautinoa ai le tulaga lelei o le setete saoloto. E leai se ofuina i le taimi o le faʻaaogaina, e faʻaauau pea ona toe fai ma mautu mo se taimi umi.

11. Faiga fuaina o meafaigaluega

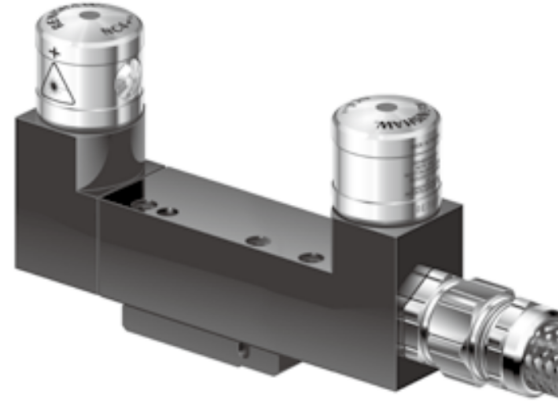

O le masini meafaigaluega ua faʻapipiʻiina i le Renishaw NC4 leisa meafaigaluega seti meafaigaluega, o le toe fuaina o le ± 0.1um, ma le vevela galue o le 5 ° C i le 50 ° C.

12. Five-axis saʻo calibration

O loʻo faʻapipiʻiina le masini masini KKH calibration polo mai HEIDENHAIN, faʻatasi ai ma suʻesuʻega faʻasologa TS, e ausia ai le faʻavasegaina saʻo o le axis rotation meafaigaluega, faʻaitiitia mea sese i le taimi o le masini masini, ma ausia le maualuga maualuga ma le toe faʻaleleia.

(1) Malosiaga: 380V±10% 50HZ±1HZ tolu-vaega AC

(2) Vaʻavaʻa vevela: 5°C-40°C

(3) O le vevela sili ona lelei: 22°C-24°C

(4) Susū fa'atusa: 40-75%

(5) Faʻasalaga punaʻau: ≥6 pa

(6) Faʻasalaga puna kesi: 500 L / min

15. Galuega fa'aofiina o le CNC system

HEIDENHAIN TNC640 CNC faiga

(1) Numera o to'i: e oo atu i le 24 matasele fa'atonutonu

(2) Pa'i fa'aaliga mata fa'atasi ma fa'agaioiga tele-pa'i

(3) Polokalame fa'aoga: Klartext talanoaga ma le G code (ISO) polokalame

(4) FK free contour programming: fa'aoga le Klartext gagana polokalame fa'atalanoaga e fa'atino ai polokalame fa'ata'ita'i fua FK fa'atasi ai ma le lagolago fa'ata.

(5) Taamilomilo vili ma vili tele

(6) Taui meafaigaluega: taui radius meafaigaluega ma taui umi meafaigaluega. Taamilosaga su'esu'e

(7) Otiotiina o faʻamaumauga: Faʻatulagaina otometi o le saoasaoa o le spindle, le saoasaoa o le tipi, fafaga i le lau ma fafaga i le liʻo.

(8) Saosaoa fa'agaoioiga fa'asologa faifaipea: fa'atatau i le ala o le nofoaga autu o meafaigaluega / fa'atatau ile pito meafaigaluega

(9) Parallel Run: Polokalama fa'atasi ai ma ata fa'atusa a'o fa'agasolo le isi polokalame

(10) Elemene ta'amilosaga: laina sa'o/chamfer/arc ala/li'o totonugalemu/li'o radius/tangentially feso'ota'i arc / tulimanu lapotopoto

(11) Fa'alatalata atu ma alu ese mai fa'ata'amilosaga: fa'atasi po'o le fa'atutusa/i ala arc.

(12) Polokalama oso: fa'asolo/polokalame poloka toe fai/so'o se polokalame e mafai ona avea ma fa'atonuga

(13) Ta'amilosaga tu'u apa: viliina, tata'i (fa'atasi pe leai fo'i se fa'avaa fa'afefeteina), fa'afa'afa'afa'afa'afa'afa'afa'afa'afa'afa'afafa'a (arc cavity). viliina Peck, reaming, le manaia, faafesaga'i mata, vili mata. Milina filo totonu ma fafo. Fa'asa'asa'a o luga mafolafola ma fa'aifo. Machining atoatoa o taga faatafafa ma lapotopoto, fatu faatafafa ma lapotopoto. Ta'amilosaga talatala ma fa'amae'a mo va'a sa'o ma lapotopoto. Fa'asologa o togi i li'o ma laina. Fa'asologa o mea: QR code. filifili filifili, taga Contour. Fa'ailoga fa'ailoga mo le viliina o trochoidal. Ta'amilosaga togitogiga: togitogia tusitusiga po'o numera i luga o se laina sa'o po'o le arc.

(14) Fa'amaopoopo suiga: fa'aliliuga, feliuliua'i, fa'ata fa'ata, fa'afuafua (axis fa'apitoa).

(15) Q parameter fesuia'i polokalame: galuega fa'a-matematika, fa'agaioiga fa'atatau, fa'agaioiga puipui, fa'atauva'a, þ faifaipea, negation, integer po'o le decimal, galuega fa'atatau li'o, galuega galue o tusitusiga.

(16) Polokalame fesoasoani: calculator. Se lisi o fe'au sese uma o iai nei. Fa'atino fesoasoani fa'apitoa mo fe'au sese. TNCguide: faiga fesoasoani tu'ufa'atasi; o le TNC 640 faʻaalia faʻamatalaga saʻo mai le tusi faʻaoga. Lagolago fa'akomepiuta mo polokalame ta'amilosaga. Fa'amatalaga poloka ma poloka autu i polokalame NC.

(17) Mauaina o faʻamatalaga: faʻaaoga saʻo le tulaga tonu i le polokalame NC.

(18) Fa'ata'ita'iga fa'amaonia polokalame: Fa'ata'ita'iga fa'ata o fa'agaioiga masini e mafai ona fa'atino tusa lava pe fa'agasolo se isi polokalame. Va'aiga pito i luga/va'aiga tolu-dimensional/va'aiga fa'alogo, ma va'alele fa'agasolo fa'agasolo/3-D laina ata. Fa'alotoifale fua.

(19) Fa'apolokalame lagolago ata: E tusa lava pe fa'agasolo se isi polokalame, e mafai ona fa'aalia ata (2-D tusilima su'ega ata) o le vaega o le polokalame NC fa'aofi i totonu o le fa'atonuga o le fa'atonutonuina o polokalame.

(20) Polokalama fa'ata'ita'i ata: fa'ata'ita'iga ata fa'atusa i taimi tonu a'o fa'atino le polokalame vili. va'aiga pito i luga/tolu va'aiga/va'aiga tu'ufua.

(21) Taimi fa'agaioiga: Fa'atatau le taimi e fa'agasolo ai i le faiga fa'atino o le "su'ega". Fa'aali le taimi o masini o lo'o iai i le "Program Run" fa'agaioiga faiga.

(22) Toe foʻi i le taʻavale: faʻaalia le taimi o loʻo i ai nei i le faʻaogaina o le "polokalame taʻavale". Polokalama faʻalavelave, alu ese ma toe foʻi i le taʻavale.

(23) Fa'atonu le fa'atonuga: o se laulau mo le fa'asaoina o so'o se mea fa'atulaga.

(24) Origin table: tele laulau amata, fa'aoga e fa'asaoina ai le tupuaga o le mea faigaluega.

(25) 3-D Machining: Faʻatonuga o Gaioiga o le High Quality Smooth Jerk

(26) Taimi faiga poloka: 0.5 ms

(27) Faʻamatalaga faʻapipiʻi ma faʻaalia laasaga: 0.1 μm

(28) Fua o le taamilosaga: fa'avasegaina o su'esu'ega. Tusia po'o otometi taui o mea faigaluega misalignment. Seti mea fa'atulaga ma le lima pe otometi. Meafaigaluega ma mea faigaluega e mafai ona fua otometi.

(29) Taui sese: mea sese laina laina ma nonlinear axis, backlash, fesuiaʻi maʻai tulimanu o le gaioioiga lapotopoto, liliu sese, faalauteleina vevela. fe'ese'esea'i, fe'ai fa'ase'e.

(30) Faʻamatalaga faʻamatalaga: RS-232-C/V.24, e oʻo atu i le 115 kbit/s. Fa'alautele fa'amatalaga feso'ota'iga o le LSV2 protocol, fa'aoga HEIDENHAIN TNCremo po'o le TNCremoPlus software e fa'atino mamao ai le TNC e ala i lenei fa'amatalaga fa'amatalaga. 2 x Gigabit Ethernet 1000BASE-T fa'aoga. 5 x USB ports (1 pito i luma USB 2.0 ports, 4 USB 3.0 ports).

(31) Su'esu'ega: Mea faigaluega fa'apitoa mo su'esu'ega mo fa'afitauli vave ma faigofie.

(32) Faitautusi CAD: fa'aali faila fa'asologa o le CAD.

Fa'ailoga autu

| Aitema | Vaega | Parameter | |

| Laupapa galue | Laumepa galue | mm | Φ700 |

| Tulaga maualuga faalava | kg | 500 | |

| Tu'usa'o maualuga uta | kg | 300 | |

| T-nofoa | mm | 8×14 | |

| Fa'asologa o galuega | Va'a i le va o foliga i'u ivi ma foliga pito o le laulau faigaluega (Max) | mm | 600 |

| Va'a i le va o foliga fa'ai'u fa'apolofesa ma foliga fa'ai'u (Min) | mm | 150 | |

| X axis | mm | 700 | |

| Y axis | mm | 550 | |

| Z axis | mm | 450 | |

| B axis | ° | -35~+110 | |

| C axis | ° | 360 | |

| Spindle | Taper | BT40 | BT40 |

| Fa'atatau le saoasaoa | rpm | 2000 | |

| Max. saoasaoa | rpm | 15000 | |

| Manuia fa'aoso S1/S6 | Nm | 72/88 | |

| S1/S6 malosi afi afi | KW | 15/18.5 | |

| Tu'u | X axis Saosaoa fa'asao vave | m/min | 36 |

| Y axis Saosaoa felauaiga vave | m/min | 36 | |

| Z axis Saosaoa fa'asao vave | m/min | 36 | |

| B axis Max. saoasaoa | rpm | 80 | |

| C axis Max. saoasaoa | rpm | 80 | |

| X/Y/Z malosi afi afi | Kw | 3.6/3.6/2 | |

| B/C axis afi afi malosi | Kw | 13.3 / 3.7 | |

| B/C axis fa'amauina torque | Nm | 2540/700 | |

| Mekasini meafaigaluega | Ituaiga |

| Ituaiga tisiki |

| Meafaigaluega filifilia |

| Filifiliga meafaigaluega pito lata ane e lua | |

| Malosiaga | T | 30 | |

| Max. umi meafaigaluega | mm | 300 | |

| Max. mamafa meafaigaluega | kg | 8 | |

| Max. tipi tipi tipi (Meafaigaluega Atoatoa) | mm | φ80 | |

| Taimi pito sili ona tipi tipi (Meafaigaluega gaogao lata ane) | mm | φ150 | |

| Sa'o | Tulaga fa'amalosia |

| GB/T20957.4 (ISO10791-4) |

| Fa'atonu sa'o (X/Y/Z) | mm | 0.008/0.008/0.008 | |

| Fa'atonu sa'o (B/C) |

| 7″/7″ | |

| Sa'o fa'atonuga | X-axis/Y-axis/Z-axis | mm | 0.006/0.006/0.006 |

| B-axis/C-axis |

| 5″/5″ | |

| mamafa | kg | 8000 | |

| Malosiaga | KVA | 45 | |

Lisi Fa'atonu Fa'atonu

| Leai. | Igoa |

| 1 | Vaega autu (e aofia ai le moega, koluma, ipu fa'ase'e, nofoa fa'ase'e, fa'auluulu) |

| 2 | X, Y, Z faiga fafaga tolu-axis |

| 3 | Laulima Ta'otoga Ta'otoga Ta'oto BC630 |

| 4 | Lisi eletise BT40 |

| 5 | Faiga fa'aeletise (e aofia ai le kapeneta eletise, fa'aogaina o le eletise, servo module, PLC, vaega fa'atino, fa'aaliga, iunite fa'apipi'i, fa'aalili eletise eletise, ma isi) |

| 6 | Fua fa'amau: HEIDENHAIN |

| 7 | Fa'apalapala |

| 8 | Pneumatic faiga |

| 9 | Fa'atotonugalemu faiga lubrication |

| 10 | Suau'u-ea lubrication faiga |

| 11 | Fa'a'ave'ave mea pu'e, tane vai, fa'aputu mea'ai: RAL7021 lanu uliuli |

| 12 | Vai malulu |

| 13 | Mea faigaluega e fua ai mea faigaluega: HEIDENHAIN TS460 |

| 14 | Meafaigaluega fa'atulagaina: Renishaw NC4 |

| 15 | Fa'ata'ita'iga sa'o e lima: HEIDENHAIN KKH |

| 16 | Leoleo nofoaafi |

| 17 | Meafaigaluega masini ufi puipui atoa |

| 18 | Fa'avae ile tasi itu ole fa'aogaina ole HPMILL post-processing software, fusifusia le tuatusi fa'aletino ole komepiuta |

| 19 | Spindle thermal elongation taui galuega |